Purpose of experimentation:

What is an experiment?

Change in Input → Process → change in output

Process → machines, materials, methods, people, environment, measurements

What are the important input factors, and how do they influence the output?

1) Improve performance characteristics:

Identify critical factors

Reduce scrap and rework

2) Reduce costs

3) Shorten production development time

Example system input and outputs for product optimization:

What is experimental design?

Using efficient and effective experimentation procedures to get the most information you can the fastest you can.

Most efficient way to collect data?

.

.

.

.

Use historical or happenstance data

AKA, just use what is already out there.

Risks – undocumented/unknown factors present in non-experimental data.

Example:

Does changing temp in wire bonding process increase the number of defects in the product?

Does changing temp in wire bonding process increase the number of defects in the product?

Undocumented factor:

Lab operator was changing the standard temperature settings without recording altered temperatures.

Hold temperature constant, just change pressure.

Lab operator was changing the standard temperature settings without recording altered temperatures.

.

.

.

Change one factor at a time.

example:

Hold Pressure constant, just change temperature.

Hold temperature constant, just change pressure.

Do the above tables contain all possible combinations of (T,P)?

No (P2,T1) is missing.

What about interactions between factors?

If factors interact with one another,

Example: Testing the effects of heart medication and grapefruit juice on health. (Cannot test grapefruit juice independently of medication, as they interact with one another)

If factors interact with one another,

one-at-a-time testing is inadequate to determine results.

- Works well if there are only a few input factors

- Impossible if there are many input factors

Combination of (P2,T1) is not contained in the one-at-a-time tables. What if (P2,T1) provides the optimal result?

Full Factorial Design

Test all possible combinations of input factors

- Works well if there are only a few input factors

- Impossible if there are many input factors

Example – what if there are 12 different input factors?

12 input factors, each tested at two different values

(T1, T2, P1, P2, % C1, %C2, etc.)

.

State specific goals

Example experiment goals:

analyze o-ring materials for use in rocket booster seal. Quantify temperature and loading-rate dependence of material strength properties.

Gather background information through research and meetings

Example Objective:

Create stress-strain diagrams for rubber which shows strength properties as a function of temperature

2^12 combinations = 4096 combinations to test! impossible!

Robust Design:- Eliminate testing factors that cannot be changed or controlled.

- Use statistical tools to determine the most important combinations to test.

Planning your experiment:

State specific goals

Example experiment goals:

analyze o-ring materials for use in rocket booster seal. Quantify temperature and loading-rate dependence of material strength properties.

Gather background information through research and meetings

Meet with

- Management,

- engineers,

- subject matter experts,

- operators,

- analysts

- type of rubber

- temperature (room temp, freezing, and room temp)

- loading rate

- age of rubber

- exposure (sun, humidity)

- other treatment options

List of outputs

- yield point,

- young's modulus,

- shape of stress strain curve

- friction coefficient

- Define safe operating temperatures and pressures for o-ring seals

Create stress-strain diagrams for rubber which shows strength properties as a function of temperature

How many levels per input?

possible experiments to run:

Create stress-strain diagrams for 3 different temperatures (frozen, room temp, 100°C)

Test multiple types of o-ring materials

Test old and new o-rings to quantify how properties change with time

test under different pressures

possible experiments to run:

Create stress-strain diagrams for 3 different temperatures (frozen, room temp, 100°C)

Test multiple types of o-ring materials

Test old and new o-rings to quantify how properties change with time

test under different pressures

*1.18 Tree diagram

Taking Data:

Uncertainty Analysis:

Errors in Physical Measurements

Mean:

xi = each individual data point

u = mean

N = number of data points

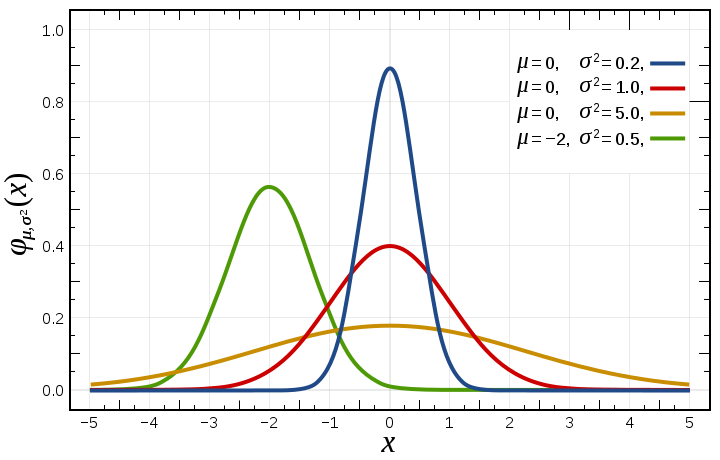

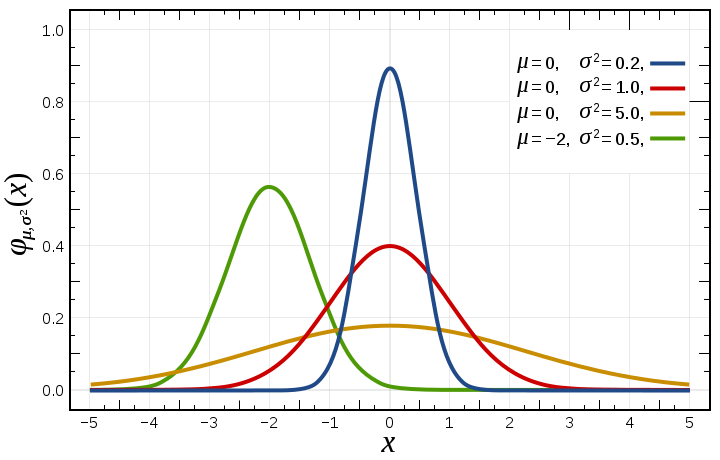

Gaussian (Normal) Distribution,

or common probability distribution.

(Take a bunch of data, probability that data will fall within a certain range)

Project:

Experimental design: test project build

Data sheets in excel

Tables should have

*1.4 Design Matrix Table

Conducting the experiment:

- Adhere to clearly defined and agreed upon operating procedures

- Prepare data sheets in advance

- Repetition & error tolerances

- Analyze data, Draw conclusions, make predictions, do confirmatory tests

Causation vs. Correlation

- A causes B

- B causes A

- A and B are both consequences of the same cause

- Some combination of 1, 2, and 3

- A and B unrelated, correlation is pure coincidence.

Taking Data:

- Repeat each measurement 4 times

- Compare the data you get to the data others get - is it repeatable?

- What is the error in measurement?

Uncertainty Analysis:

Errors in Physical Measurements

- X = True Value

- xi = measured value

- n = number of measurements taken

- Accuracy = how close xi is to true value X

- Precision = how good grouping is

Mean:

- Median = midpoint in events (½points below, ½ points above)

- Mode = most frequently occurring value

- Error = ei = Deviation from true value: ei = xi - X

- We do not (and cannot) know X - so - Approximate X by the mean µ

- ei* = xi - µ

- ei* approximates ei and is called an estimator of ei.

- Random deviations: Human errors, normal distribution

- Systematic deviations: Calibration errors

- Relative Error = DX/X -or- = ei/m

- Variance

- Standard Deviation = width of distribution, estimate of average error

- Standard Deviation of Mean (SDOM)

u = mean

N = number of data points

Gaussian (Normal) Distribution,

or common probability distribution.

(Take a bunch of data, probability that data will fall within a certain range)

Example of different distributions taken with different precision -

- low standard deviation = data points very close to the mean

- high standard deviation = data points spread out over a large range of values.

Project:

- Review technical communication notes,

- Walk through engineering method,

- Problem statement, Goals, Research, .... testing

- Experimental Design: Materials list, procedure, data sheets,

Experimental design: test project build

- Testing: Construction, fill in data tables, graphs, error analysis

- Conclusion, review, and recommendation for further tests.

Data sheets in excel

Tables should have

- Place to record all inputs

- Copies of tables to record multiple trials - repeat each measurement at least 4 times

- Standard deviation, mean, mode for repeated trials

- Room for additional notes and comments.

- Graphs comparing results

- Conclusions: is design safe? energy efficient? what modifications could be made? Your project build will be just a model, in report include notes on what materials and design you would use if given more time and resources.